Products

The belt conveyor feed the bags into the machine, the cutter device to get the bags cut, the materials get separated from the bag by rolling drum screen and fall into the storage hopper . The empty bag can be automatically collected and compacted by waste bag compactor.

It is suitable for places with large space, large amount of unpacking, high dust control requirements.

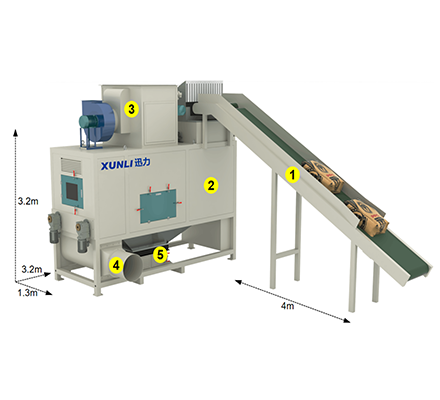

| Num | Part name | Description |

| 1 | Belt conveyor | Convey the bags into the machine of bag slitter |

| 2 | Bag slitter | Cut open bag, separate the material and the bag |

| 3 | Dust collector | Ensure the negative pressure inside the machine, dust does not spill |

| 4 | Empty bag compactor | Automatic collection, compaction of the empty bags |

| 5 | Hopper | Material outlet |

Capacity:

600-1000 bags/hour (depending on fluidity of material)

Emptying rate:

99.9%-99.99% (depending on the fluidity of material)

Overall power:

about 10KW

Compressed air:

about 100L/ min / 0.6mpa

Weight of equipment:

about 3 tons

Above technical parameters are subject to change due to different equipment specifications.

High applicability: suitable for different kind of materials in different size of bags.

High emptying rate: 99.9%-99.99% high emptying rate, almost no material left in empty bags.

No dust leakage: Equipped with dust collector, there is no dust leakage during the operation

Easy to use/easy to maintain: PLC automatic control, one click-start, simple installation, reliable operation

添加迅力技术微信

解决拆包机所有问题