Products

Through the roller conveyor line, the entire stack will be automatically conveyed into the catching position of bag slitter, the catching device of the bag slitter will come down to grab the whole layer bags layer by layer, and raise up to the set position, then move inside the machine, during this process the cutter blade will cut open the bags from the bottom, material emptying device to empty the material inside the bag, the material by gravity fall into the hopper, empty bag into the waste bag compactor, which collect, compact and extrude out the waste bag.

When the whole stack bag is unpacked, the roller conveyor line will automatically transport the empty pallet to the pallet collector to complete automatic collection and stacking of the empty pallet.

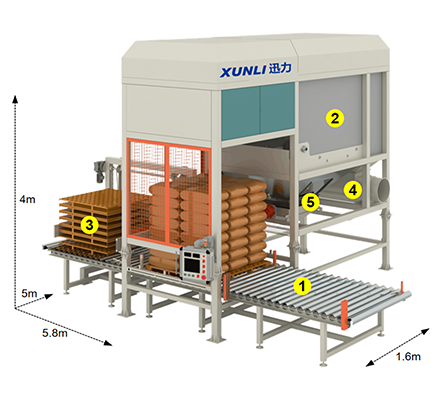

| Num | Part name | Description |

| 1 | Stack conveyor | Convey the stacked bags into the machine of bag slitter |

| 2 | Layer bag slitter | Cut open bag, separate the material and the bag |

| 3 | Pallet palletizer | Collect and pile up de pallets |

| 4 | Empty bag compactor | Automatic collection, compaction of the empty bags |

| 5 | Hopper | Material outlet |

Processing capacity:

up to 650bags/hour (depends on material fluidity, etc.)

Applicable stack specifications:

length ≤1350MM, width ≤1300MM, height ≤2200MM (including pallet)

Emptying rate:

about 99.97%-99.999% (depending on material fluidity, etc.)

Overall power:

about 12KW

Compressed air:

about 150L/ min / 0.6mpa

Weight of equipment:

about 4 tons

High integration: the equipment integrates the functions of automatic stack feeding, bag catching, bag emptying, pallets collection and collection &compaction of empty bags.

Intelligent control: PLC built-in program, one click-start, unpacking speed adjustable, automatic fault alarm.

High emptying rate: above 99.97%-99.999% high emptying rate, close to 0. material left in empty bag.

Easy maintenance: the equipment is equipped with access doors to facilitate the maintenance of various components outside the equipment.

No bag debris: through special design, less bag debris generated during the cutting process, equipped with XUNLI debris filter box, almost 0 debris into the material

添加迅力技术微信

解决拆包机所有问题